Failure Mode Effects Analysis (FMEA) |

您所在的位置:网站首页 › failure mode effects analysis › Failure Mode Effects Analysis (FMEA) |

Failure Mode Effects Analysis (FMEA)

|

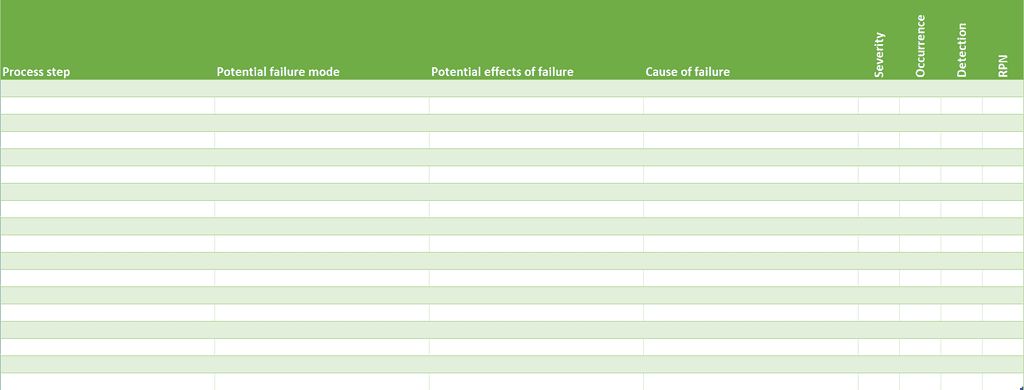

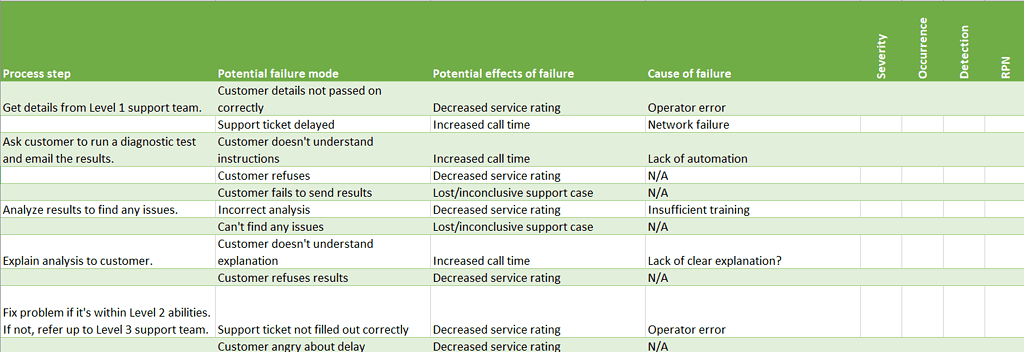

Failure Mode Effects Analysis (FMEA) is a tool that helps us anticipate what might go wrong with a product or process. We can also use it to identify the possible causes and probabilities of failures. What’s a Failure Mode?A failure mode is a chance for a process to go wrong. Or, to look at it another way, it’s an opportunity for a defect or variation to occur in a product. Every process has potential weak spots. If we can recognize these in advance, we go a long way toward minimizing the damage caused. That’s why FMEA is such a handy tool. When to Use FMEAPerform a FMEA when you’re: Setting up a new process before you start running it in a production environment. Improving an existing process. Changing an existing process – for example, modifying the type of material used. Looking for existing quality control (QC) issues within a process.The analysis can be of use in all of these situations. DMAIC PhasesYou can use a FMEA in the Analyze and Improve phases of a DMAIC project, which will depend on the purpose of your project. If your project aims to find issues in an existing process, then you’ll perform the FMEA in the Analyze phase. This is to help you figure out where things are already going wrong. If your project has another aim鈥搊ther process improvements, adding a new process, etc.鈥搕hen the FMEA’s use is a bit different. Then, you’ll use it in the Improve phase to look for issues in your solution to the problem. You’re essentially double-checking yourself. Types of FMEA Design (DFMEA)A DFMEA focuses on a product or service. You’ll typically do these before you put a new product or service into manufacture or when you change the design of either. When you perform one, you look at potential failures, safety issues, and regulatory concerns with the end product. Then you rank the severity of these. The next step is to find causes for those potential issues. Use a DFMEA to minimize the effects of product failure on your customers. By the end of your DFMEA, you should have strategies in place to correct all design issues identified. Process (PFMEA)A PFMEA looks at a process. Unlike a DFMEA, it looks at the end product or service only to find issues with the process that produced it. More commonly, you’ll look at the output from the process instead. Why are these two things different? Because most products and services are the result of multiple processes, not just one. For example, a digital camera has many parts, each of which is produced using at least one process鈥搊ften more. To find an issue with the shutter, for example, you’d look at processes that produce the shutter and processes that fix the shutter into the camera. Start a PFMEA at or after the feasibility study and before production begins. Typically, you’ll perform a PFMEA after the DFMEA, as the latter is focused on design, and the PFMEA is focused on how you bring the design to life. System (SFMEA)Also known as a functional FMEA (FFMEA). A System Failure Modes and Effects Analysis looks at the entire system on a high level. When you perform one, you look at things like the interrelationships between components and processes. An SFMEA can be useful because problems don’t just occur within processes or specific machines. They also occur between multiple processes or machines. Perform a SFMEA before the design phase where possible. This helps you to anticipate and work through issues that would otherwise affect your DFMEA. Further reading on SFMEAs InputsYour inputs for an FMEA typically come from people who know the process, product, service, or system very well. You’ll usually sit down and brainstorm potential failure points with these subject matter experts. MeasurementsDuring the FMEA process, you’ll need to provide three key scores: Severity: How large the consequences of a failure mode will be. Some effects could be catastrophic (think a nuclear power plant meltdown). Others might be very mild (for example, a slight variation in product weight). Occurrence: How likely the failure mode is to occur. Some failures might be very likely – for example, a laptop computer overheating outdoors in summer in Texas. Others might be very unlikely – for example, the nuclear power plant meltdown mentioned in the previous list item. Detection: How capable the current processes are to detect the failure. If this failure mode occurs, will the responsible person know about it straight away?These all use a scale from 1 to 10. You’ll note that these are somewhat subjective – you can’t simply use a tool to measure any of them. If you find that your team has trouble reaching a consensus on the scorings, try taking individual scores and calculating the mean score for each. Note: Some people use a scale of 1-5 instead. As long as you’re consistent, the scale you use isn’t too important. OutputsThe main output from an FMEA is a Risk Priority Number (RPN) for each failure mode. The RPN is an objective priority measure for fixing any failure mode or failure mode effect. The bigger the RPN, the higher the priority. The formula for calculating an RPN is: RPN = Severity * Occurrence * Detection How to Create a FMEAThe first step in creating a failure modes and effects analysis is understanding your goal. We’ve listed the basic types of FMEA above; read through these and decide on what type of analysis you’ll be performing and what the end result should be. Before starting the FMEAYour preliminary work will depend on the analysis you plan to perform. Essentially, you need to ensure that the whole team understands what you’re analyzing so that you can brainstorm potential failure modes. PFMEA: Map your process. Draw a flowchart so that you have a visual representation of the entire process. DFMEA: List the attributes of your product or service. What it does, its measurements (services can have these too!), parts, etc. SFMEA: Map the components of your system. An interrelationship diagram might assist. Writing your FMEA Get your team together and brainstorm possible failure points in your process, product, service, or system. For each possible failure point, list the effects that failure could have. Draw up a blank table with columns for: Process step Potential failure mode Potential effects of failure Cause of failure Severity Occurrence Detection RPN Enter the steps from your flowchart into the Process step column. Leave a few rows between each. Add failure points for each step into the Potential failure mode column. Leave a couple of rows between each. Enter the effects each failure could have into the Potential effects of the failure column. For each effect: Add a cause. Enter a score for the scale of the consequences of the effect in the Severity column. Enter a score for the likelihood of the effect in the Occurrence column. Add a score for the probability of detecting the failure effect in the Detection column. Calculate the RPN for effect by multiplying the effect’s Severity, Occurrence, and Detection scores. Enter this number in the RPN column. Your next stepsSo you’ve created your FMEA document. Your job doesn’t finish there. Next, look at ways that your team can modify the product, service, system, or process to decrease RPN scores. It would be overly simplistic for this article to suggest always working on the highest-scored (hence, highest priority) failure modes first. However, that can be done in a vacuum. Other sort-orders are possible. For example, ASQ recommends “The team should use their experience and judgment to determine appropriate priorities for action.” (source) Once you’ve lowered the risks of failure modes as much as is feasible, add two more columns to the FMEA: Recommended action Responsibility.Then: Add at least one recommended action. This is a process that should be followed if the potential failure effect actually occurs. Enter the name or job of the person who will be responsible for carrying out the recommended action(s). Example of Using a FMEA in a DMAIC ProjectA company is putting together a new customer support department. As part of that process, it’s developed a number of processes for various customer queries. The Level 2 support team must complete a design FMEA for one of its processes. PreliminariesThe team’s process analyst puts together a flowchart of the process. It shows the team five high-level steps in the process: Get details from the Level 1 support team. Ask the customer to run a diagnostic test and email the results. Analyze results to find any issues. Explain the analysis to the customer. Fix the problem if it’s within Level 2 abilities. If not, refer to the Level 3 support team. Constructing the blank FMEAThe team lead uses Excel to create a spreadsheet for the FMEA.  Image: Blank FMEA table in Excel

Adding process steps Image: Blank FMEA table in Excel

Adding process steps

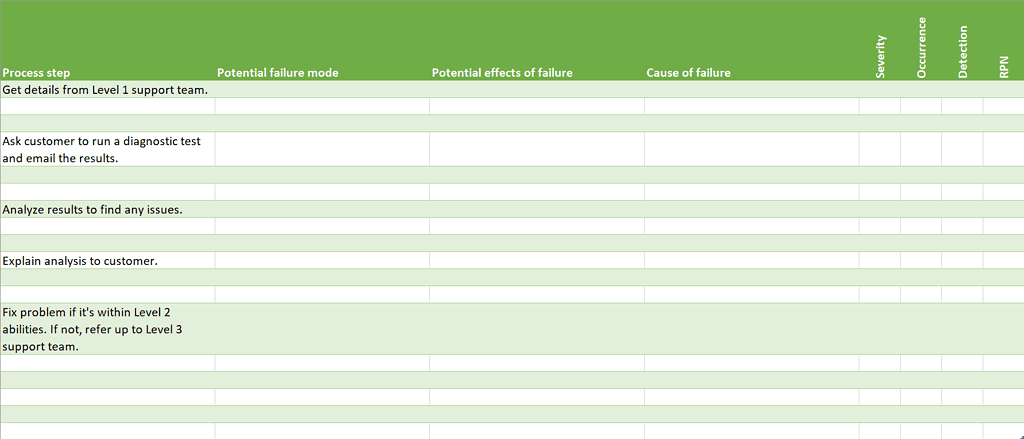

They add the five high-level process steps to the FMEA table.  Image: FMEA table with process steps filled in

Brainstorming failure modes Image: FMEA table with process steps filled in

Brainstorming failure modes

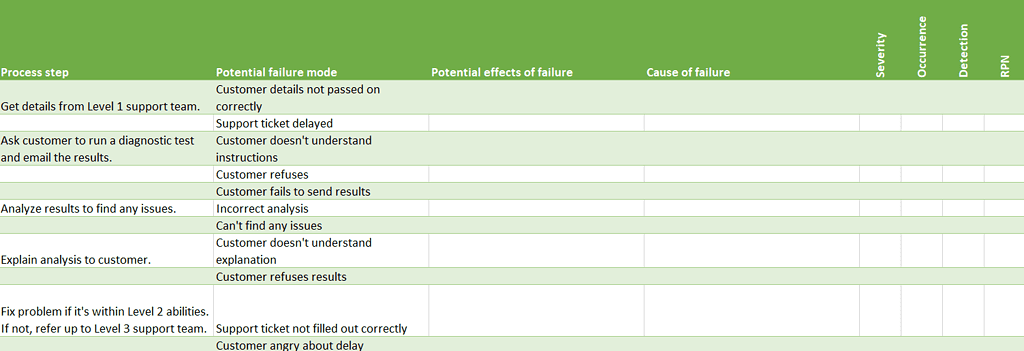

The team sits down together with the incomplete FMEA table. They discuss the process steps and brainstorm things that could go wrong. Once they’ve talked through all options, they enter the agreed failure modes.  Image: FMEA table with failure modes filled in

Recording potential effects Image: FMEA table with failure modes filled in

Recording potential effects

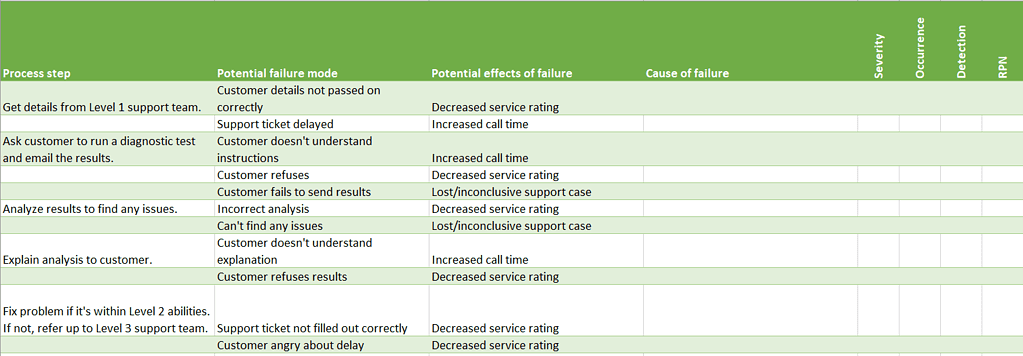

The team record effects of each failure mode, sticking to objective measures that affect KPIs.  Image: FMEA table with potential failure mode effects filled in

Finding causes Image: FMEA table with potential failure mode effects filled in

Finding causes

While some situations might require a tree diagram or other tools to chart potential causes, the team decides that this situation doesn’t need anything too complex. They record causes where the issue would reasonably originate in the customer service teams.  Image: FMEA table with failure causes added

Scoring Image: FMEA table with failure causes added

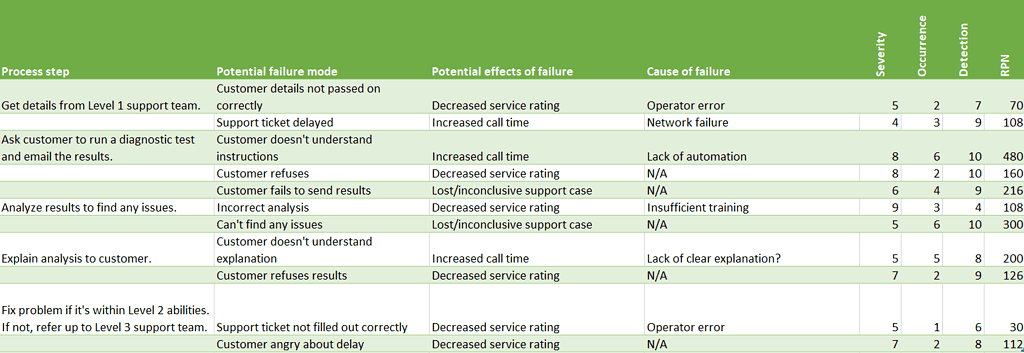

Scoring

The team used a simple discussion method to score Severity, Occurrence, and Detection for each failure effect. Then, they calculate the RPN for each by multiplying the three scores.  Image: Complete initial FMEA

Prioritizing Image: Complete initial FMEA

Prioritizing

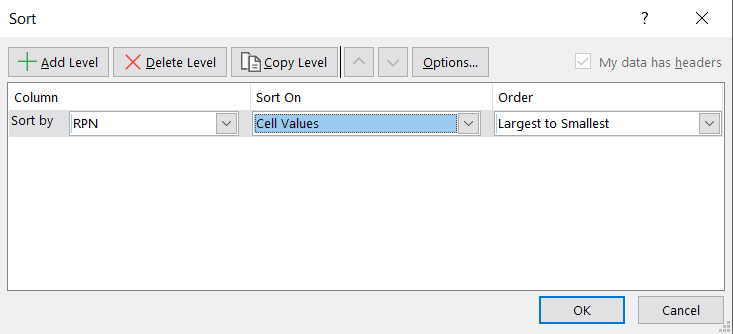

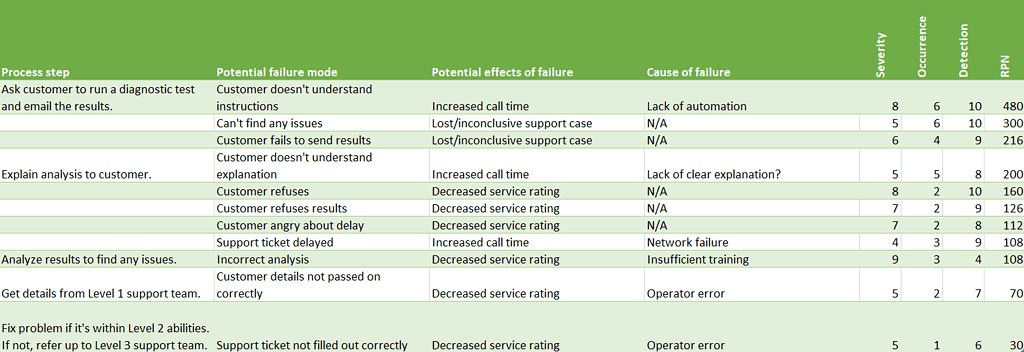

The team sorts the spreadsheet from highest to lowest RPN.  Image: Screenshot of Excel sort window Image: Screenshot of Excel sort window

Image: Initial FMEA, prioritized

Next steps Image: Initial FMEA, prioritized

Next steps

Now that the team has a prioritized list of failure modes, it can get to work on mitigating them. Beginning at the top of the list, they’ll work on decreasing the RPN: by making the failure less severe or less likely to occur. On the other hand, making it harder to detect isn’t generally recommended. Once the team has decreased the RPNs for its FMEA as much as possible, it adds a basic response plan for each failure mode. FMEA Excel Download Unlock Additional Members-only Content! To unlock additional content, please upgrade now to a full membership. Upgrade to a Full Membership If you are a member, you can log in here. Additional FMEA ResourcesStep-by-step guide. Six Sigma Black Belt Certification FMEA Questions:Question: A Six Sigma team has been chartered to improve the way in which a company takes orders for its products. Which of the following tools should the team use to determine all of the potential pitfalls and the actual defects that occur? (Taken from ASQ sample Black Belt exam.) (A) Process failure mode and effects analysis(B) Process map(C) Design for six sigma(D) Supplier input process output control Answer: Unlock Additional Members-only Content! To unlock additional content, please upgrade now to a full membership. Upgrade to a Full Membership If you are a member, you can log in here.Question: A black belt is developing a failure mode and effects analysis (FMEA) for the hamburger preparation station in a fast-food restaurant. The following ratings were developed for the low-heat temperature failure mode. Severity = 9Occurrence = 2Detection = 1 What is the risk priority number (RPN) for this FMEA? (A) 4(B) 6(C) 12(D) 18 Answer: Unlock Additional Members-only Content! To unlock additional content, please upgrade now to a full membership. Upgrade to a Full Membership If you are a member, you can log in here. AuthorsI originally created SixSigmaStudyGuide.com to help me prepare for my own Black belt exams. Overtime I've grown the site to help tens of thousands of Six Sigma belt candidates prepare for their Green Belt & Black Belt exams. Go here to learn how to pass your Six Sigma exam the 1st time through! View all posts View all posts |

【本文地址】